Sunrise ALS Series

Sunrise ALS Series

Description

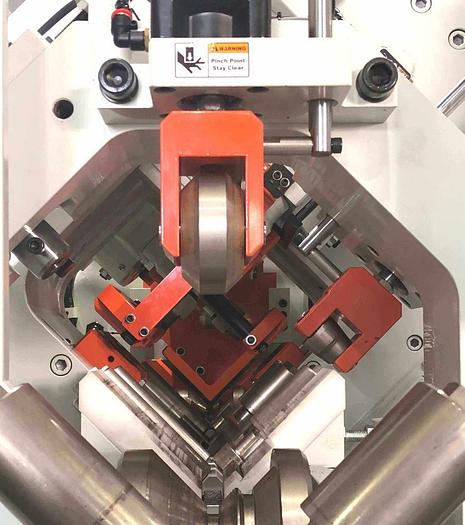

The Sunrise Angle Line System – ALS – is a versatile and fully automated angle line processing system that efficiently processes angles and flat bars up to 6″ x 6 x 1/2″. It offers punching, shearing, and dot-peen marking capabilities, enhancing accuracy and productivity in metal fabrication applications. Operation: The operator loads the angle onto the all-steel in-feed rollers; the system engages and pneumatically clamps the material, measures the length, and then processes the material by automatically punching both legs of the angle and shearing (without a slug) to length utilizing the industrial strength rack and pinion drive system. When the bar is complete, the system will automatically retract, drop the 6″ scrap, and move to the load position to repeat the process. Capacities: Shearing – 170 Ton Shear: Angle: 2″ x 2″ x 1/4″ up to 6″ x 6″ x 1/2″ – No Slug Loss – Capable of 1″-3″ x 3/16″ Angle with Special Tooling Optional Flat Bar: 2″ x 1/4″ up to 6″ x 1/2″ – No Slug Loss Punching – Dual 60 Ton Punch Cylinders: 1.5″ up to the rated tonnage – Material – 65,000 PSI Tensile. 2 independent punches per leg Minimum 1″ gauge line or 0.75″ with special tooling. Uneven leg angle is supported – the gauge line is based on the taller leg. Positioning Speed: Up to 50′ per Minute – Variable Speed Accuracy: +/- 0.004″/ Foot In-Feed Length: 20′ Standard – Expandable to 50′. (Manual outfeed sections available) Get to know the ALS Series

Standard Features

15″ Touch-Screen Windows Controller featuring multi-program memory, nesting ability, multiple pattern templates, DXF/NC1 Import, TeamViewer Remote Diagnostics, WiFi, USB 20′ In-Feed with Rack-and-Pinion Drive System, expandable up to 50′ Hydraulic punch stripper, hydraulic hold-down for shearing, and pneumatic hold-downs for in-feed Dual Punch Feature – Two independent punches, up to 1.5″ capacity, per leg of angle with tandem 66-ton punch cylinders No slug loss shear-cut featuring multi-sided blades, adjustable blade gap Automatic Pneumatic Material Clamping and Squaring Fully enclosed punching and shearing operations for operator safety, interlocked doors. Integrated cooling system with hydraulic oil cooler

Optional Features

Stamping/Dot Peen Marking Station Flat-bar processing Light Curtain Safety System Automatic lubrication system with programmable spray pattern. Auto-Loader for Angles

Sunrise ALS 1506D – Angle Line System Angle Processing Line | Quad -Punches | 6″ Angle | 6″ Flat Bar | Up to 50 Feet In-Feed | Rack and Pinion System

New, Angle Processing System, 20′ Rack and Pinion In-Feed, 6″ Angle, 6″ Flat Bar, Dual 66 Ton Cylinders, Dual-Punch Heads featuring 4 Punches, Dot-Peen Marking and more!

Specifications

| Manufacturer | Sunrise |

| Model | ALS Series |

| Condition | New |