Carell Corporation Galileo Series

Carell Corporation Galileo Series

Description

Galileo Series

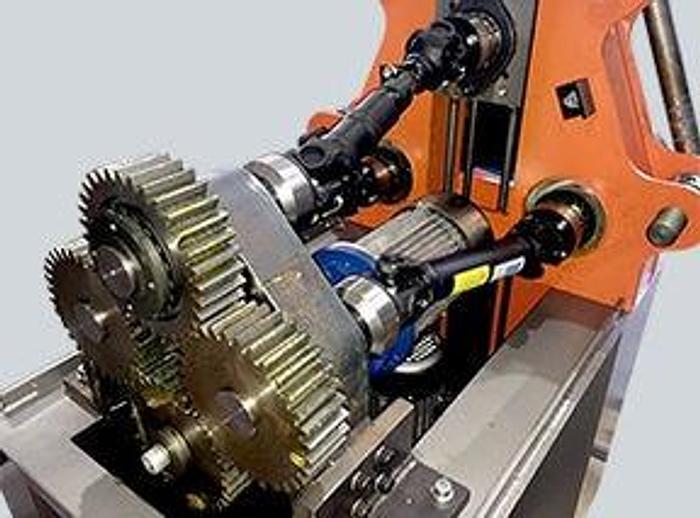

GALILEO Series G50HV & G80HVP are Heavy Duty, 3 Roll Universal Bending Machines with Solid Steel Welded Frames, LED Readouts, high strength shafts and all 3 rolls are driven through heavy duty drive trains for high torque delivery and energy efficiency. Our G50/G80 units roll standard & special sections plus tube & pipe using our unique 3 Roll Drive System with superior performance, superior design and manufacture for an attractive, economical initial investment. NO CASTINGS are used in the main frame unlike some other brands. Our Standard Universal Telescoping Modular Roll set is quick to adjust and will bend standard sections such as flat bar (on flat and on edge), square bar, tees, channel as well as round bar, angle leg-out, square and rectangular tube sections. Round tube and pipe require dedicated rolls. We manufacture custom rolls for extrusions and special shapes. Machines can be built with short shafts for dedicated coiling operations. Optional overhead supports available for coil diameter and pitch calibrations.

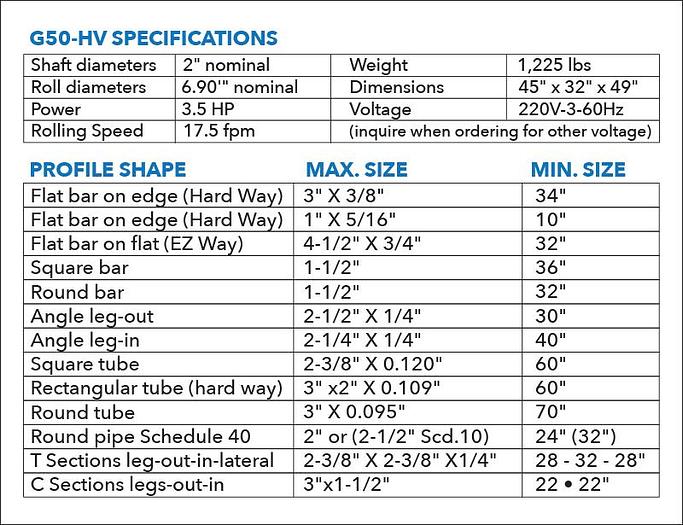

G50HV SERIES UNIVERSAL ROLL BENDERS

Capacities*

Flats Hard: 3" x 3/8" Ø34

Flats Easy: 4-1/2" x 3/4" Ø32

Pipe Schedule 40: 2" Ø24

Angle Leg-In: 2-1/4" x 1/4" Ø40

*with standard equipment

Angle 2-1/2" • Pipe 2" • Flats 4-1/2"

G50HV Series are Heavy Duty, 3 Roll Universal Bending Machines with SOLID STEEL WELDED FRAMES, LED Readouts, high strength shafts and ALL 3 ROLLS DRIVEN through heavy duty drive trains for high torque delivery and energy efficiency.

Standard Features

Rugged, Solid Steel Frames, No Castings!

Dual, Large Roller Bearings on all shafts

Hydraulic Top Roll Adjustment (HV/HVP) with push button operation

3 Driven Rolls - Automatic clutch on top roll with speed compensation

LED Readout (G50-HV)

Universal Roll Set, telescopic adjustment, Hardened to 56 HRC

Heavy Duty Multi Axis Lateral Material Guides

Vertical or Horizontal Operation is standard

Mobile Operator Consoles, 24VAC, E-Stop palm buttons

Features & Optional Tooling

3 Rolls Driven:

Heavy Duty Drive Train

Scroll Tool: 1-1/2 x 3/16 Scrolled on Flat

Bar Twist Tooling:up to 7/8” Sq. and 1-1/2” x 3/8” Flat Bar

Bar Brake

Spiral Tool

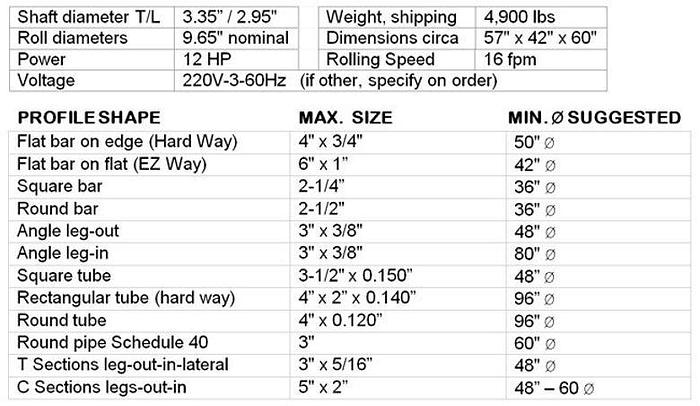

G80HV SERIES UNIVERSAL ROLL BENDERS

Capacities*

Flats Hard: 4" x 3/4" Ø50

Flats Easy: 6" x 1" Ø42

Pipe Schedule 40: 3" Ø60

Angle Leg-In: 3" x 3/8" Ø80

*with standard equipment

Angle 3" • Pipe 3" • Flats 6"

G80HV Series are Heavy Duty, 3 Roll Universal Bending Machines with SOLID STEEL WELDED FRAMES, LED Readouts, high strength shafts and ALL 3 ROLLS DRIVEN through heavy duty drive trains for high torque delivery and energy efficiency.

Standard Features

Rugged, Solid Steel Frames, No Castings!

Dual, Large Roller Bearings on all shafts

Hydraulic Top Roll Adjustment (HV/HVP) with push button operation

3 Driven Rolls - Automatic clutch on top roll with speed compensation

Programmable Readout (G80-HVP)

Universal Roll Set, telescopic adjustment, Hardened to 56 HRC

Heavy Duty Multi Axis Lateral Material Guides

Vertical or Horizontal Operation is standard

Mobile Operator Consoles, 24VAC, E-Stop palm buttons

Specifications

| Manufacturer | Carell |

| Model | Galileo Series |

| Condition | New |