Transfluid t form SRM Roll Forming Machines

Transfluid t form SRM Roll Forming Machines

Description

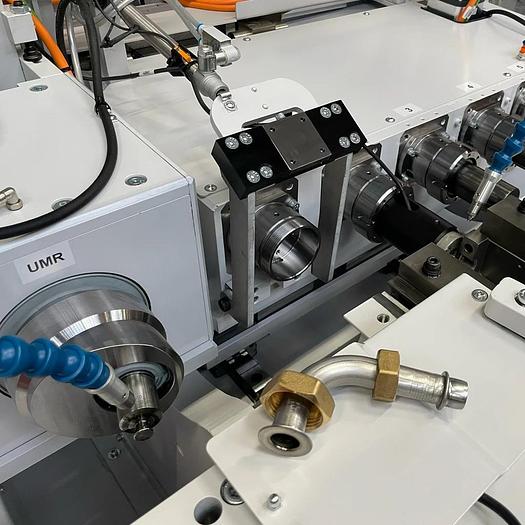

t bend - Type SRM rollforming machines Our multi tool - All options in one single machine! - Forming, cutting, post-bending cutting, threading. - For extreme forming degrees with highest precision - Multiple machining steps possible in one cycle - High machining speeds of up to 1500 rpm - Low energy consumption and highest precision due to servo drives transfluid® t form SRM ROLLFORMING MACHINES Powerful and fast forming. Our rotational technology increases the possibilities of forming on tubes with minimal expenditure on tools. All the drives are servo-electric by design and, if needed, CNC-operated. In our SRM rollforming machines, all the settings are preloaded, so there is no longer any need for costly adjustments. Different tool variants further expand the processing possibilities for chipless cutting or post-bending cutting. The machines can produce internal and external profiles and can also roll in synchronicity thanks to a special tool head (inside/outside). T FORM ABSOLUTE INNOVATION: CUTTING AND FORMING WITH ONE TOOL Multidimensional and automated bending of tubes. Highly efficient CNC bending technology for small and big bending tasks with the greatest precision. Our fully automated solutions mean optimum cycle times and large production volumes. The outstanding flexibility of our advanced CNC tube bending machines gives you economical bending process and meets the most demanding requirements. PREPARED FOR INTEGRATION INTO PRODUCTION CELLS This series will win you over with its special stability and performance. Individual pieces and small series can be produced in an extremely economical manner with this machine concept. The use of high-value components ensures the machine‘s durability. EASY CONTROL VIA TOUCH PANEL Setting of all parameters centrally in the machine control system, controlled positioning of the forming axis and the stop position. The UMR is equipped with a completely electronic preselection of the flanging geometry. The stop position and all strokes and machining operations are servo-electrically controlled and can be called up via a touch panel.

Decisive for the exact machining time is which material is used and which shaping is to be implemented. The machine carries out the processing quasi automatically if it is possible to call up the tube size with the necessary process parameters. In individual cases, the clamping lengths for machining are 1 to 1.5 x the pipe diameter. Our new generation of t form UMR 628, 642 and 2090 machines reduces the set-up time when changing the tools and the operator can set up the machine in less than three minutes.

Specifications

| Manufacturer | Transfluid |

| Model | t form SRM Roll Forming Machines |

| Condition | New |

| Max. capacity | 3/16" - 7/8" in |

| Wall thickness | .035" in |

| Rpm | 300 - 1000 |

| Cycle time adjustable | 4 - 10 sec. |

| Operation length | max. 40 mm |

| Clamping length | 1,0 x D |

| Power | 4 kW |

| Weight | 2750 lb |

| L x w x h | 79 x 35 x 79 in |