Serra Laser/IPG LightWELD

Serra Laser/IPG LightWELD

Description

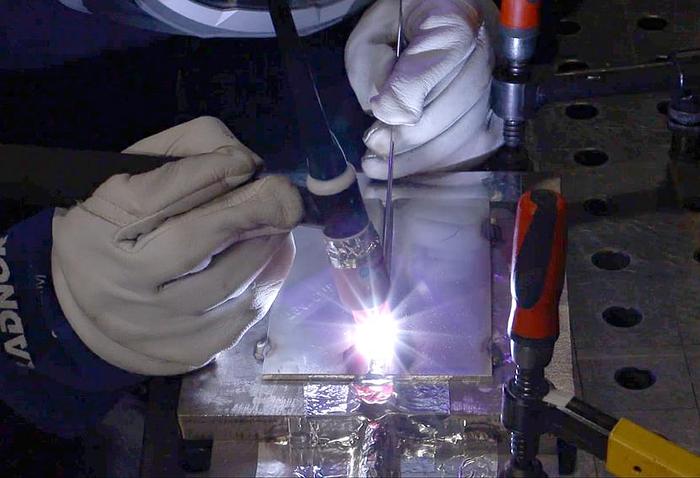

LightWELD - Handheld Laser Welding & Cleaning Systems

4x Faster than TIG

Up to 0.315" Welding Capability

100 Welding & Cleaning Presets

Prepare to be amazed!

Made in the US to ensure full control over product quality, LightWELD® handheld laser welding and cleaning systems are designed to revolutionize your weld quality and productivity. LightWELD laser welding is fast, easy to learn, and produces high quality, consistent results across a wide range of materials and thicknesses. Pre-weld and post-weld laser cleaning functionality optimizes weld quality while increasing productivity.

Power Up: Introducing the NEW LightWELD 2000 XR

More power means more productivity. Level up your shop and weld and clean even faster with industry-leading laser output up to 2000 W.

Fast and Easy Setup

Built-In Presets for Optimized Welds

Welding Steel, Aluminum, Copper, Titanium, Nickel Alloys

Cleaning Pre- and Post-Weld

Live Q&A

LightWELD 2000 XR - High-Power Laser Welding & Cleaning

LightWELD 1500 XR - Extended Range Laser Welding & Cleaning

LightWELD 1500 XC - Laser Welding & Cleaning

LightWELD 1500 - Laser Welding

LightWELD

LightWELD enables dramatically faster welding, is easier to learn and operate, and provides higher-quality, consistent results across a wider range of materials and thicknesses than MIG or TIG with minimal distortion, deformation, undercut or burn-through.

Factory Presets Ensure Optimized Welds & Cleaning

- Simple preset selection ensures consistent high-quality laser welds and cleaning

- Presets include wobble welding function to accommodate wider seams and for parts with poor fit-up

- Operators can instantly switch between presets to process multiple material-thickness combinations

- Advanced operators can customize presets, save for future use and can be used by novice operators to produce the same results

- Novice operators require less training which reduces labor costs while preserving quality, increasing productivity, and decreasing scrap

Fast & Easy Set Up

220 V Power - Clearly labeled rear connections make getting started fast and easy.

Standard Gas - Laser power, gas, and gun control are delivered through a single cable.

Workpiece Clamp - Attach clamp to work surface and the system is ready to go.

Connectivity - An ethernet connection provides access to advanced parameter settings.

Operator Safety Features

- Key switch control to secure system from unauthorized operation

- Emergency stop button for immediate shut down

- Safety interlock verifies integrity of laser delivery to the welding gun

- 2-step weld gun trigger, enable and then fire, for intentional operation

- Part contact electrical interlock turns off the laser power if the welding head is not in contact with the welded parts

- Specially designed welding helmet and laser safety glasses

- Door switch interlock circuits shut down laser if anyone other than operator unexpectedly enters the welding area

Maximize Productivity with a Collaborative Robot System

Free up skilled welders to focus on more complex welds with the LightWELD Cobot System, a high-precision laser welding collaborative robot.

Powered by LightWELD laser welding and cleaning technology, this flexible system enables shops to maximize productivity with no-fuss automation of repetitive welding jobs. No robot or programming experience required.

Weld thick, thin, reflective, and dissimilar metals that are difficult or impossible with traditional methods, as well as materials with different electrical conductivity.

- High-speed welding across a wide range of materials and thicknesses

- Low heat input for minimal part distortion or deformation

- Built-in factory presets for all materials and thicknesses

- Weld with or without wire

Pre-Weld Cleaning

LightWELD XC and XR models only

- Contaminants can enter the weld pool and compromise weld integrity

- Pulsed cleaning power up to 2500 W peak power evaporates undesired surface elements

- Fast and effective removal of contaminants such as oxides, rust, paint, oil, or grease from surface without the use of chemicals or abrasives

- Up to 0.6" of adjustable cleaning width with one pass

Post-Weld Cleaning

LightWELD XC and XR models only

- Post-weld cleaning removes soot, debris, or any sign of localized heating

- Dramatically reduces time, cost, and scrap

- Create visually appealing welds while eliminating need for post-grinding

- Up to 0.6" of adjustable cleaning width in one pass

Built-in Wobble Welding

- Simple on-the-fly control of up to 0.2" of additional weld width with selectable frequencies for parts with imperfect fit-up

- Creates wider, more attractive seams

- Wobble parameters are preprogrammed and can be saved by the operator and recalled immediately as needed

- In cleaning mode, the wobble function provides adjustable cleaning scan widths up to 0.6"

Optional Wire Feeding Package

- Wire welding capability extends laser welding applications to increase the weld bead size or overcome poor part fit-up

- Can be used for stainless steel, mild steel, galvanized steel, nickel alloys, aluminum, copper, and brass

- Wire feed speed range 40 – 0.4 - 230 ipm (1 - 600 cm/min)

- Wire diameter capacity 0.030" - 0.063" (0.8 mm - 1.6 mm)

- Wire feed tips: 0.030", 0.035", 0.045", 0.063" (0.8 mm, 0.9 mm, 1.2 mm, 1.6 mm)

- 4X V-groove drive rolls and steel liners for hard wire, 4X U-groove drive rolls, and Teflon liners for soft wire

- Package includes wire feed unit, electrical connections, nozzle assembly, and LightWELD wire welding presets

Specifications

| Manufacturer | Serra Laser |

| Model | LightWELD |

| Condition | New |