NS ML100

NS ML100

Description

Max Ø 114mm

Straight and curved tube1 station

1 Station

Straight and curved round tube finishing up to Ø114mm with maximum flexibility and consistency.

Tube polishing machine – ML100 – is the perfect choice for finishing the surface of round, oval, and elliptical tubes.

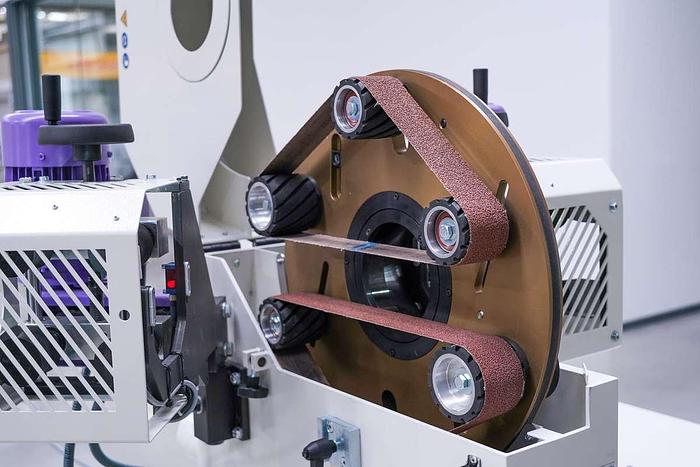

The ML planetary system allows the work to be done without rotating the tube, delivering the best results on both bent and curved tubes.

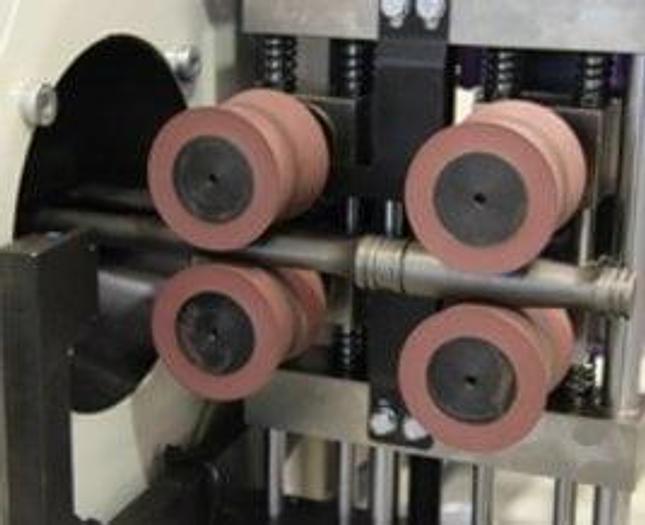

The auto feeding system transports straight tubes safely and automatically through the finishing station, delivering a consistent and highly productive tube polishing quality.

With the ML Planetary System the tube is not spinning. The abrasive belts rotate around the tube while it is safely transported by the feeding systems.

The ML100 was designed to finish either straight tubes (automatically) or bent tubes (manually).

The ML100 tube polishing machine is simple to work with. The automatic feeding system is hinge mounted and easily removable for bent tube finishing.

The light contact with the abrasive belts on the ML Planetary System generates very little heat on the surface of the tube, unlike other more conventional systems.

Oval or elliptical tubes polishing or simply out-of-round tubes can be safely and consistently finished with the ML100.

Maximum adaptability of the abrasive belt to holes or graps in the material surface.

Specifications

| Manufacturer | NS |

| Condition | New |

| Working capacity (Ø mm) | 10 - 114 |

| No. Stations | 1 |

| Abrasive belt dimensions (mm) | (2x) 50x940 |

| Abrasive belt speed (m/s) | 10-25 |

| Feeding Speed (m/m) | 1-5 |

| Wheel motor (kW) | 1.5 |

| Feeding Motor (KW) | 5 |

| Consumption (A) | 14 |

| Dust extraction connection (Ømm) | 100 |

| Dimensions (mm) | 750x1000x1300 |

| Weight (kg) | 250 |